Onsite Waste Reduction

Cleanpower Worldwide provides our clients with the most innovative Waste Reduction systems on Earth.

The end-to-end solutions we offer provide everything you need to reduce both wet and dry organic waste on-site, reducing waste disposal and energy costs, and helping your business to be on the forefront of the sustainability movement.

The end-to-end solutions we offer provide everything you need to reduce both wet and dry organic waste on-site, reducing waste disposal and energy costs, and helping your business to be on the forefront of the sustainability movement.

- Environmental benefits: Reducing waste can have a range of environmental benefits, such as reducing greenhouse gas emissions, conserving natural resources, and protecting wildlife and ecosystems. By reducing waste, a company or organization can improve its environmental performance and contribute to sustainability.

- Social benefits: Reducing waste can also have social benefits, such as improving public health, creating jobs, and supporting local communities. For example, implementing a recycling program can create jobs in the recycling industry, and reducing waste can help to protect the air and water quality in the surrounding community.

- Governance benefits: Reducing waste can also have governance benefits, such as improving compliance with regulations, enhancing transparency and accountability, and enhancing the company or organization's reputation and public image. By taking steps to reduce waste, a company or organization can demonstrate its commitment to sustainability and responsible governance.

How it Works

At CleanPower Worldwide, we provide you with everything you need to turn your dramatically reduce your organic waste.

For wet organic waste we provide industrial dehydrators to convert your waste into reusable biomass. This biomass can then be utilized to power emissions-free boilers to lower your power bill, reduce carbon emissions, and make use of waste that your business would otherwise have to pay to ship off and dispose of. Even if you don't utilize the biomass onsite to power boilers, the dehydration process alone reduces the size and weight of your waste by up to 80%, dramatically reducing your waste disposal costs and carbon and methane emissions. This biomass can also be donated or repurposed as feed or soil additive.

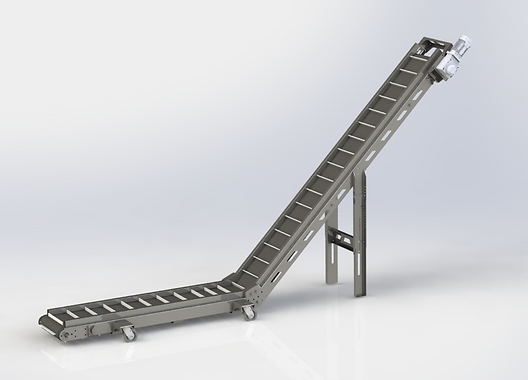

For dry organic waste, we provide shredders that reduce the waste to uniform size so that it can be added to the hopper manually or via our conveyor systems to power boilers for heating. If not intending to use the dry organic waste in boiler systems, we also provide compressors that further reduce the size of the waste and convert it into biomass briquettes that can then be shipped off and donated or disposed of at a fraction of the cost and emissions of unsorted waste.

For wet organic waste we provide industrial dehydrators to convert your waste into reusable biomass. This biomass can then be utilized to power emissions-free boilers to lower your power bill, reduce carbon emissions, and make use of waste that your business would otherwise have to pay to ship off and dispose of. Even if you don't utilize the biomass onsite to power boilers, the dehydration process alone reduces the size and weight of your waste by up to 80%, dramatically reducing your waste disposal costs and carbon and methane emissions. This biomass can also be donated or repurposed as feed or soil additive.

For dry organic waste, we provide shredders that reduce the waste to uniform size so that it can be added to the hopper manually or via our conveyor systems to power boilers for heating. If not intending to use the dry organic waste in boiler systems, we also provide compressors that further reduce the size of the waste and convert it into biomass briquettes that can then be shipped off and donated or disposed of at a fraction of the cost and emissions of unsorted waste.

Products

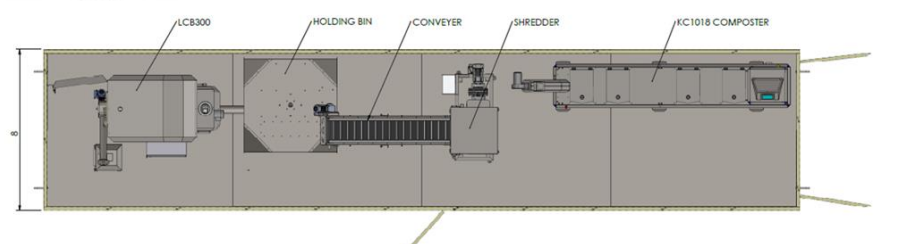

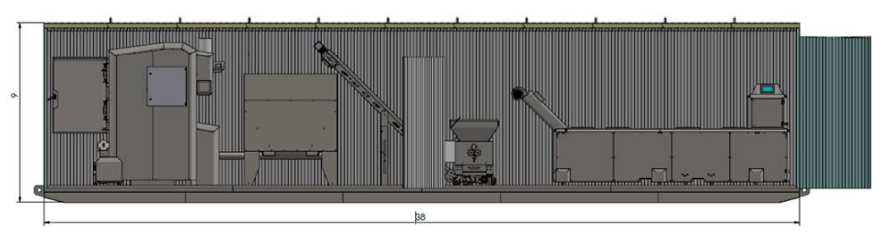

For clients looking for 99% biowaste reduction, the Plug-and-Play system includes everything your business needs to reduce organic waste into biomass to ensure proper operation and results.

Our setups allow you to tailor the equipment to the needs of your business - whether large or small - to reduce carbon and methane emissions. And the best part: Operational cost reductions by utilizing Waste Reduction technology, with your ROI varying depending on waste disposal costs. We find clients begin seeing a complete return on their initial investment anywhere from 1 to 3 years.

Our setups allow you to tailor the equipment to the needs of your business - whether large or small - to reduce carbon and methane emissions. And the best part: Operational cost reductions by utilizing Waste Reduction technology, with your ROI varying depending on waste disposal costs. We find clients begin seeing a complete return on their initial investment anywhere from 1 to 3 years.

Plug-and-Play System Designs

Equipment

Depending on the needs of your business, you can also purchase individual components of our system.

A good example of this is a business that wants to reduce the amount of waste they have to pay to dispose of. Since organic waste is approximately ~80% water on average, adding a dehydrator to your restaurant, brewery, or business reduces disposal costs while stopping methane from being released into the atmosphere.

A good example of this is a business that wants to reduce the amount of waste they have to pay to dispose of. Since organic waste is approximately ~80% water on average, adding a dehydrator to your restaurant, brewery, or business reduces disposal costs while stopping methane from being released into the atmosphere.

Case Studies

Fairmont Chateau Lake Louise, Alberta, Canada

|

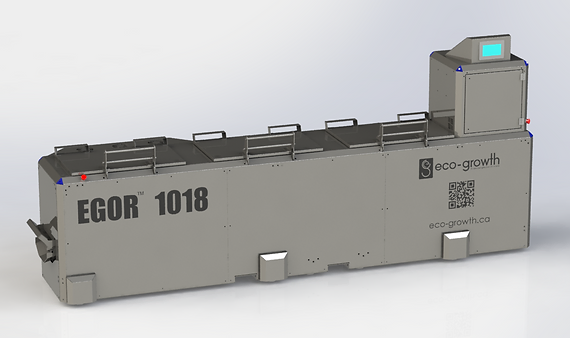

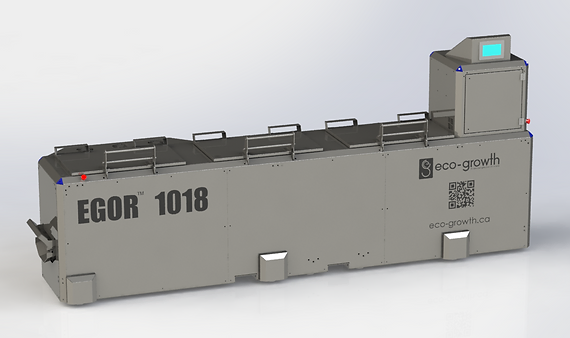

The Fairmont Chateau Lake Louise in Alberta, Canada has been utilizing a EGOR 1018 model to take food waste from the hotel's restaurants to convert it to biomass and reduce waste onsite.

The EGOR 1018 processes 500 lbs of food waste per day from the hotel, converting that waste into 100 lbs of biofuel which represents an annual savings of 65.5 metric tons of Carbon Dioxide (C02) equivalent. It would take 77.5 acres of forest to sequester this much carbon each year. |

Grizzly Paw Brewing Company

|

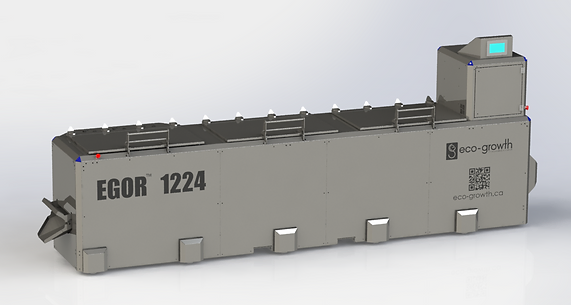

Grizzly Paw Brewing Company utilizes the largest size Waste-to-Power system we offer, the EGOR 1224 to take their spent grains and other organic waste from their brewing process to provide an on-site fuel source for their hot water boiler, saving money on waste disposal and energy.

The EGOR 1224 process 1,100 lbs of wet organics/day, producing 300 lbs of ready-to-use biofuel. *This biofuel underwent calorific testing and showed that it could create 2.0 kw/lb or 6,800 btu/lb of energy. Therefore, their 300 lbs of biofuel is able to produce 600 kw/day of clean power. The system saves an annual 132 metric tons of carbon dioxide equivalent. |

Food Co-Op in Uclutet, British Columbia

|

At a Food Co-Op in Ucletet, British Columbia, they are utilizing one of our Eco-Boiler 50's that can consume 20 lbs per hour of biomass to produce Thermal Energy.

The system operates using a 220 volt, 3 phase power drawing a max of 10 amps, consuming 50 kwh/day, but produces 1,200 kwh of usable energy for a net gain of 1,150 kwh/day of clean power or an annual 297 metric tons of carbon dioxide (CO2) equivalent. By leveraging our innovative clean power technology, the Food Co-Op is reducing massive amounts of carbon and methane emissions caused by decomposing organic material in city and county dumps. |

Contact Us today for a completely free consultation to learn more about how we can help you and your business join the Clean Power Revolution.